Shortboards

Filters

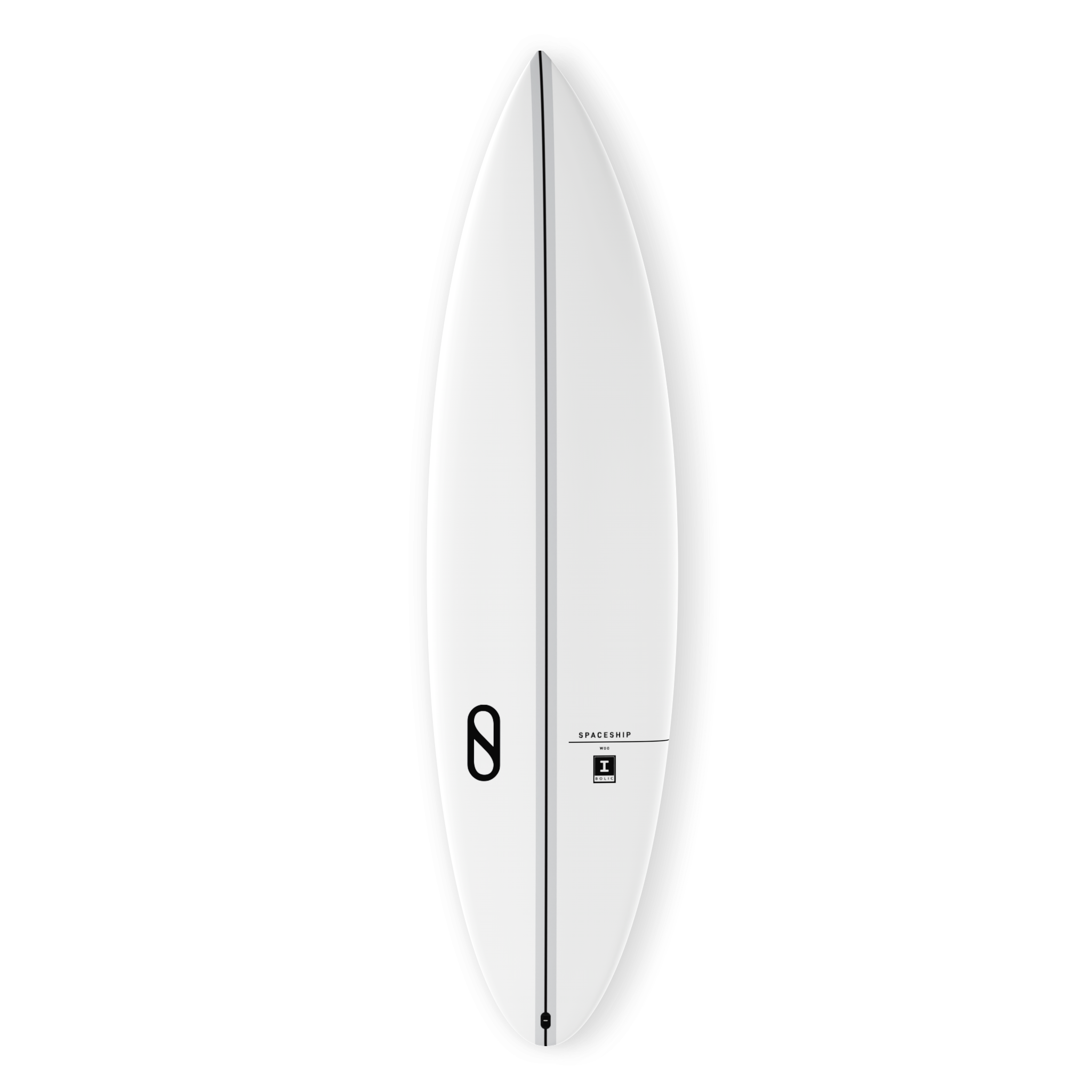

Spaceship

Sale priceFrom $890.00 USD

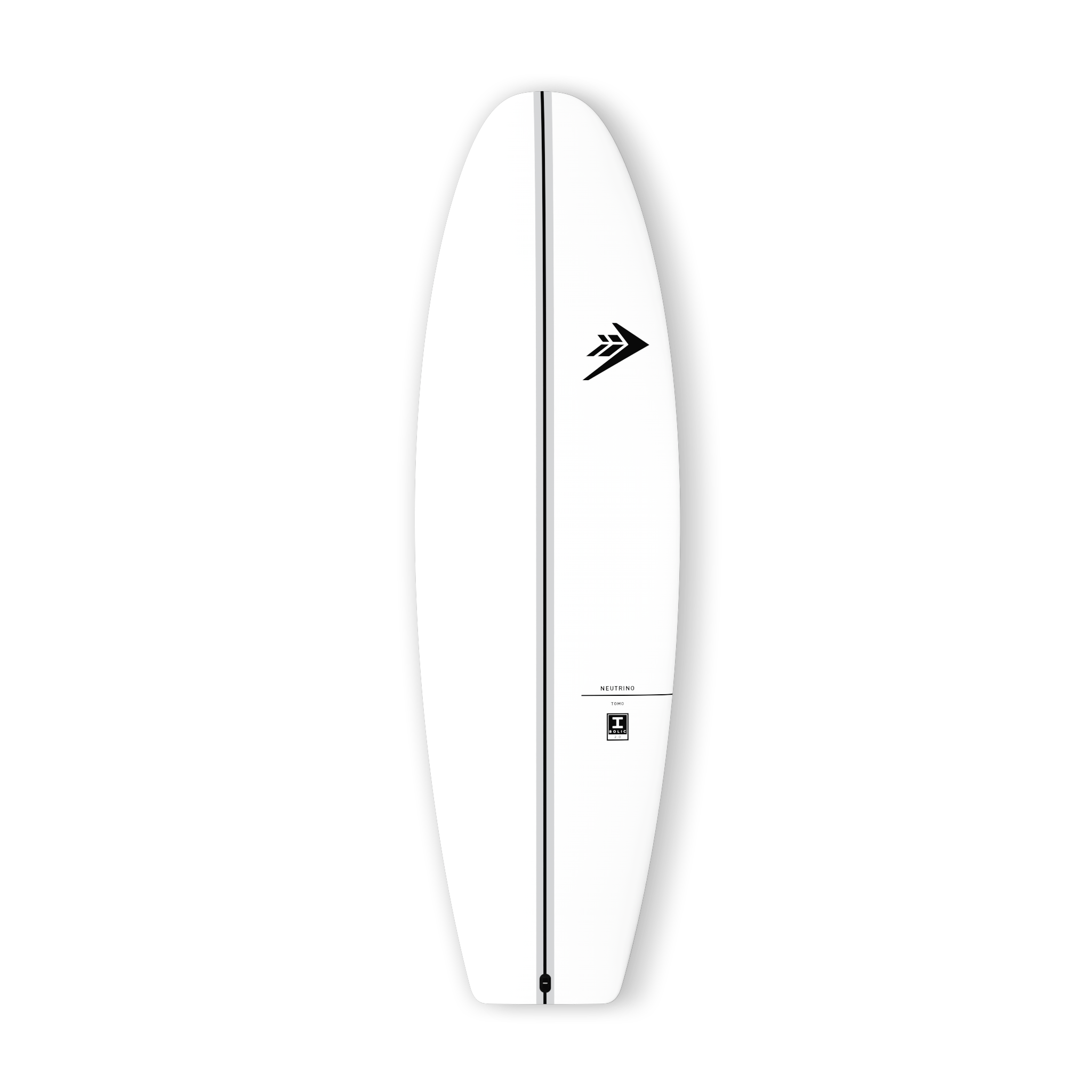

Neutrino

Sale priceFrom $890.00 USD

Dominator Pro

Sale priceFrom $890.00 USD

Dominator 2.0

Sale price$890.00 USD

Regular price

Dominator 2.0

Sale price$980.00 USD

Regular price

Groove

Sale priceFrom $890.00 USD

FRK Swallow

Sale price$890.00 USD

Machadocado

Sale priceFrom $890.00 USD

S Boss

Sale price$712.00 USD

Regular price$890.00 USD

S Boss

Sale price$784.00 USD

Regular price$980.00 USD

Great White Twin

Sale priceFrom $980.00 USD

Too Fish

Sale price$890.00 USD

Regular price

Too Fish

Sale price$980.00 USD

Regular price

Sci-Fi 2.0

Sale price$890.00 USD

Regular price

Sci-Fi 2.0

Sale price$704.00 USD

Regular price

FRK+

Sale price$890.00 USD

Regular price

FRK+

Sale price$980.00 USD

Regular price

FRK

Sale price$890.00 USD

Sweet Potato

Sale price$890.00 USD

Regular price

Sweet Potato

Sale price$980.00 USD

Regular price

Cymatic

Sale priceFrom $980.00 USD

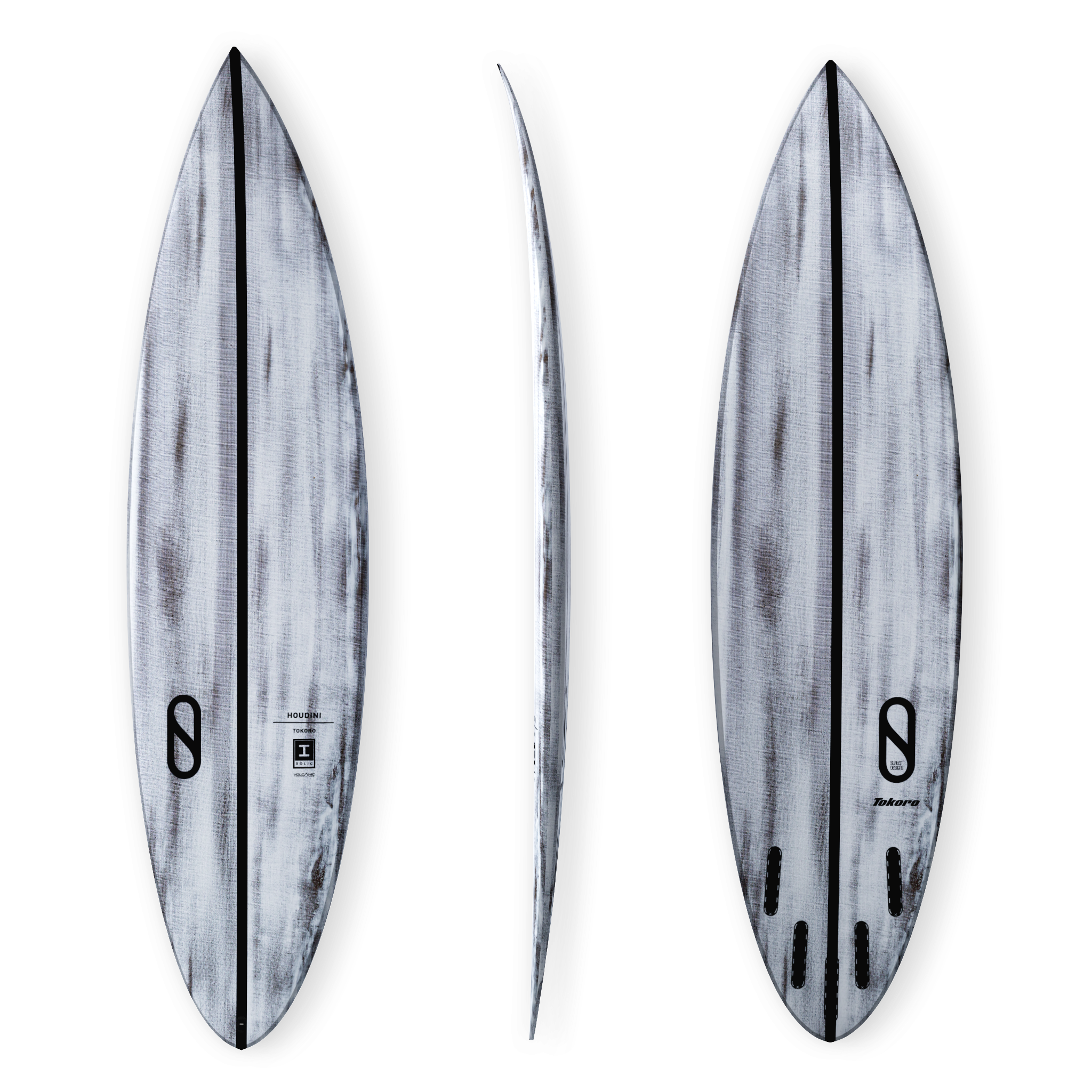

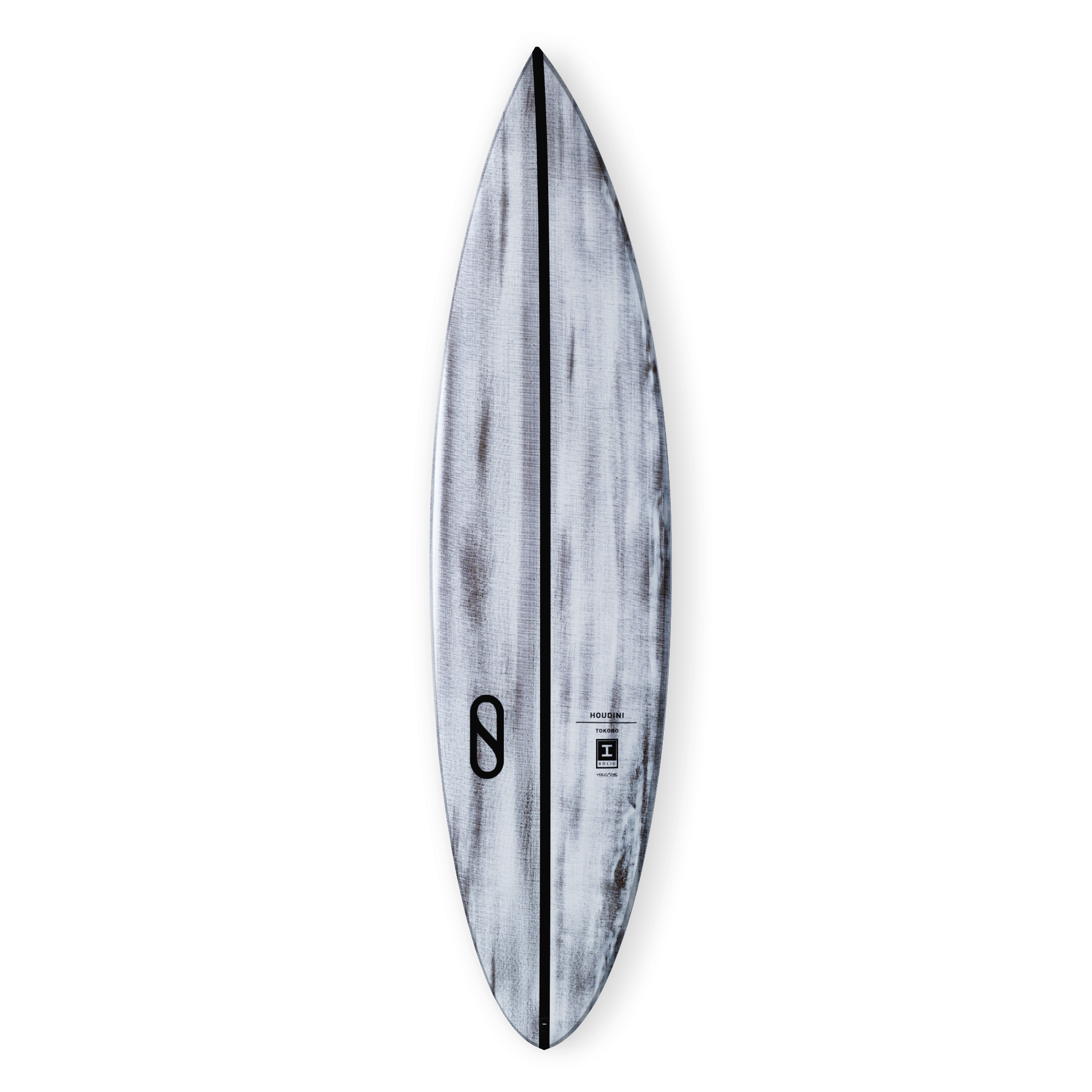

Houdini

Sale priceFrom $980.00 USD

Seaside

Sale price$890.00 USD

Regular price

Seaside

Sale price$980.00 USD

Regular price

Mashup

Sale price$890.00 USD

Regular price

Mashup

Sale price$980.00 USD

Regular price

Greedy Beaver

Sale priceFrom $980.00 USD

Revo Max

Sale priceFrom $980.00 USD

Taylor Jensen Twinzer

Sale priceFrom $960.00 USD

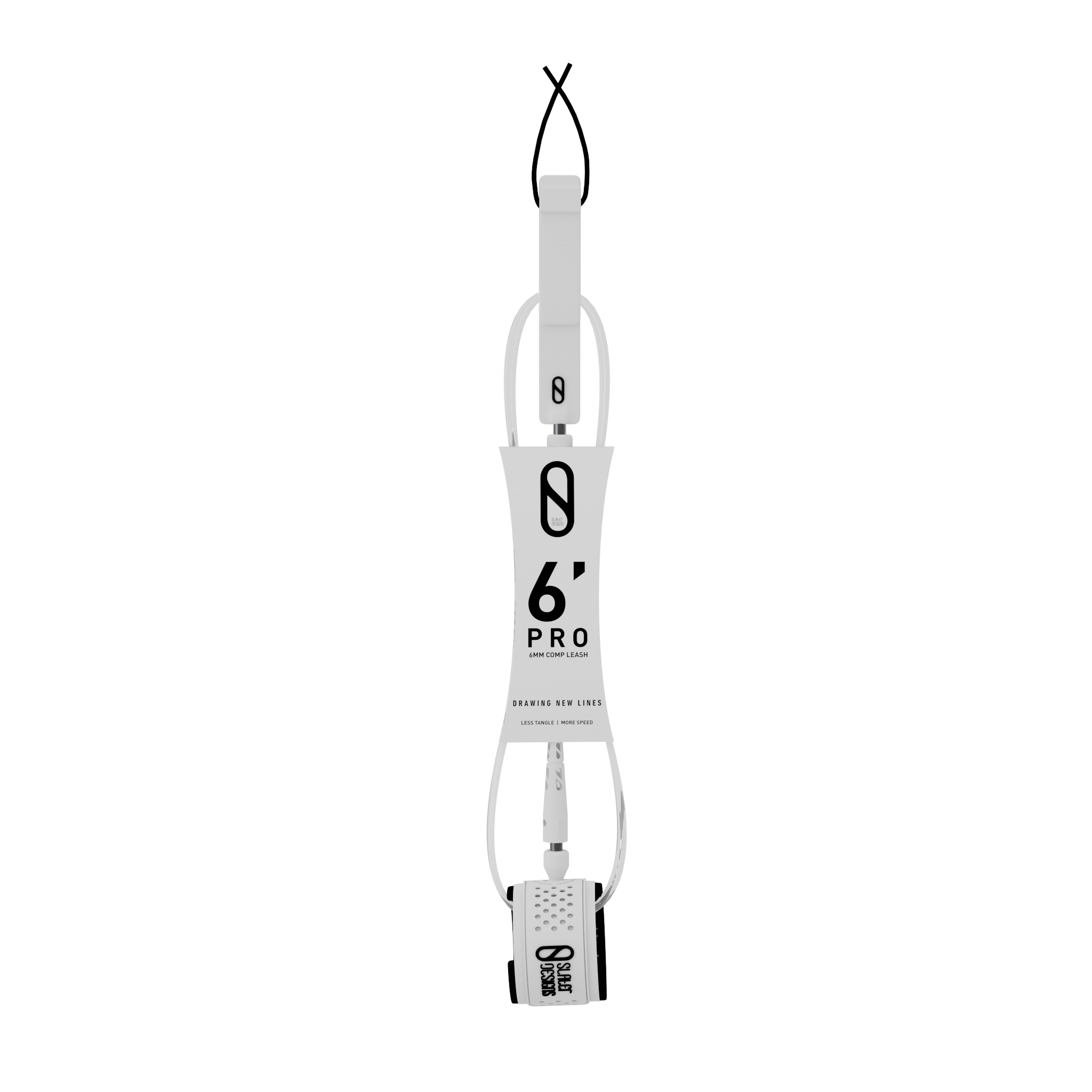

Slater Designs 6mm Comp Leash

Sale price$38.00 USD

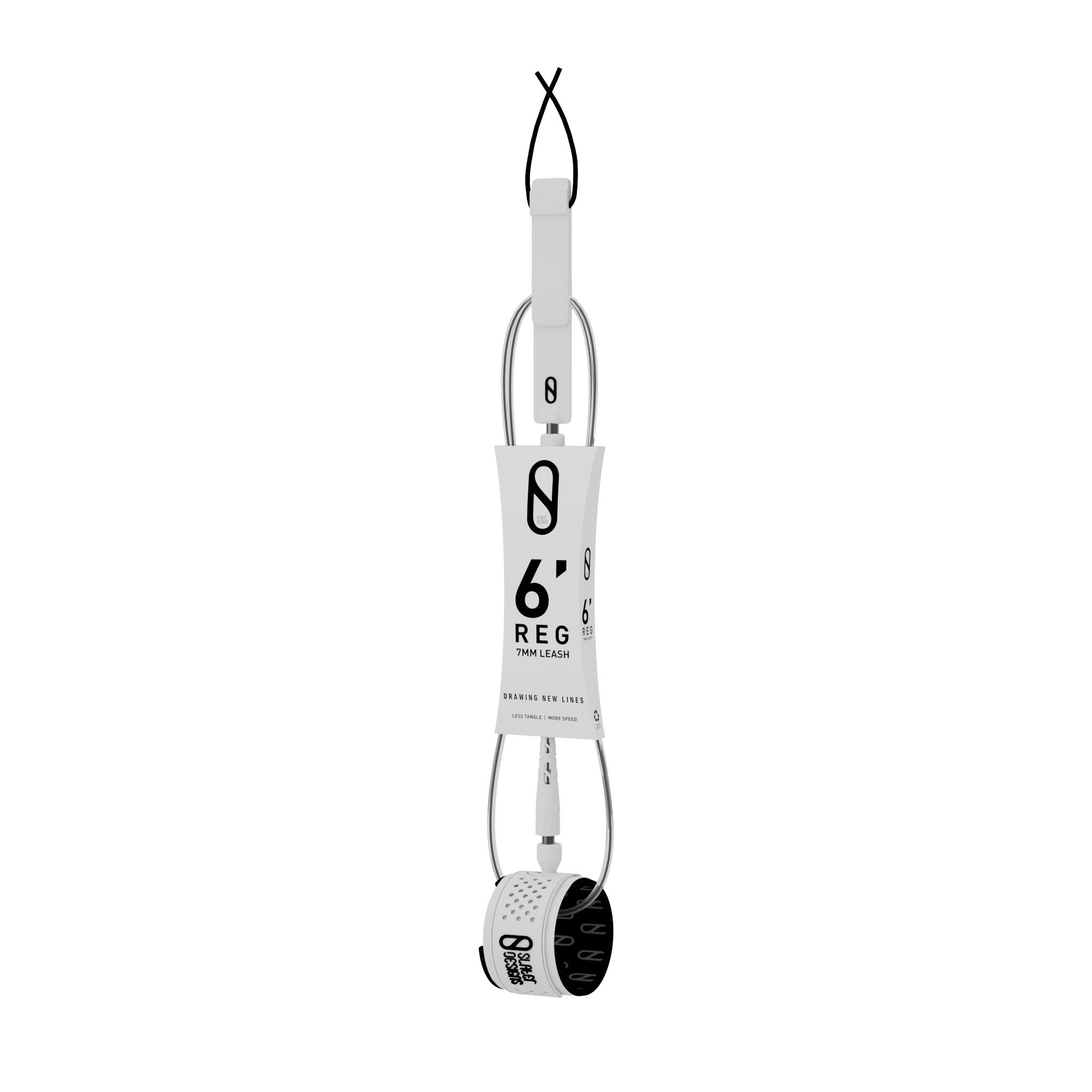

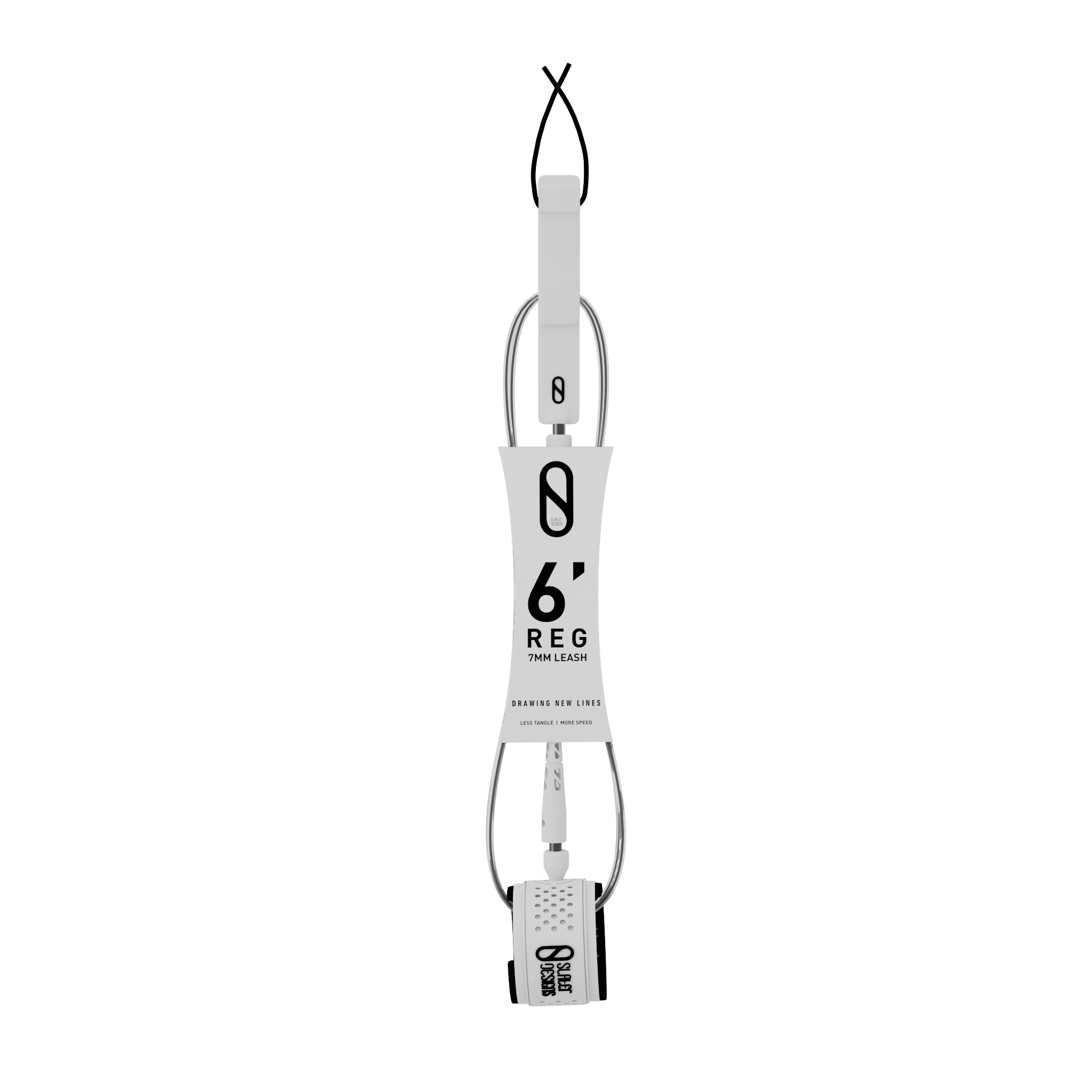

Slater Designs 7mm Regular Leash

Sale priceFrom $40.00 USD

Firewire All Day 7mm Regular Leash

Sale priceFrom $36.00 USD

Firewire Black Mesh Board Sock - Shortboard

Sale priceFrom $46.00 USD

Firewire All Day Bag - Shortboard

Sale priceFrom $92.00 USD

Firewire Black Mesh Board Sock - Hybrid

Sale priceFrom $46.00 USD

Gift Card

Sale priceFrom $50.00 USD